The innovative technological finishes in some apparel fabrics today have come a long way since scientist Ruth Benerito first helped make 100% cotton wrinkle-resistant decades ago. Now, consumers can purchase clothing that can protect them from the sun, wick moisture away from their skin, and even dry faster.

[quote]Stylesight’s Sophie-Lucie Dewulf, senior editor for materials, says research and development in textile technology continues to be vital for both business and consumers.

“Textiles need to evolve constantly, responding to ever progressing visual and tactile needs of consumers,” she says. These consumers are seeking “garments with unique style, offering higher levels of comfort and performance with healthy and ethical content. Only adequate textile engineering enables this significant purpose of up-to-date material production.”

Three-fourths of consumers agree better quality garments are made from all natural fibers like cotton, according to the Cotton Incorporated Lifestyle Monitor™ Survey. More than eight out of 10 consumers (84%) prefer their clothing to be made of cotton and cotton blends. And 79% say cotton and cotton blends are the fibers best suited for today’s fashions.

But a good chunk of consumers want clothes that are easier to care for, make them look slimmer, or keep them cooler or protected from the sun. And that is where natural tech fabrics come into play.

“We’re all trying to build a better mouse trap,” says the Fashion Institute of Technology’s Ingrid Johnson, professor and assistant chairperson, textile development and marketing. “Instead of making something and then trying to sell it to consumers, we look toward a particular market, find end uses and then make a product that works.”

Johnson says consumers can look forward to fabric that charges their electronics, or clothes that absorb heat during the day, to keep the wearer warm at night.

“Researchers are finding ways to take the energy we create and transfer it into our clothing,” Johnson explains. “It would be wonderful to capture that energy and charge our iPhones and endless array of gadgets we’re all attached to.”

Without a doubt, such apparel would be especially useful after natural disasters, like when much of the East Coast was without power for days and weeks after Hurricane Sandy last year.

“A lot of this comes from the military,” Johnson says. “We learn a lot about how to contain the environment or address it in desert areas. For instance, we needed to know how to absorb sunlight to keep soldiers cool during the day and then use it to keep them warm at night. This could be brought to the consumer market for mountain climbers, hikers, and other outdoor enthusiasts.”

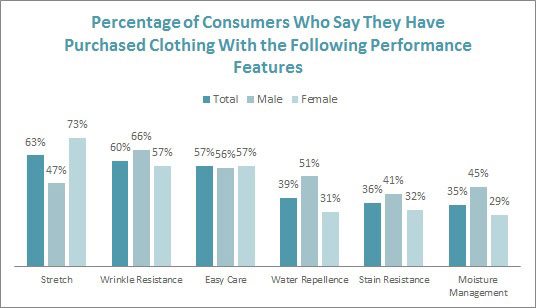

Consumers definitely appreciate tech fabrics. More than six out of 10 (63%) have purchased clothes with stretch properties, followed by wrinkle resistant (60%), easy care (57%), and water repellent (39%) apparel, the Monitor shows. Compared to responses in June 2009, significantly fewer consumers have purchased stain (44% to 36%) and fade (34% to 29%) resistant clothes, while significantly more (25% to 35%) say they have purchased moisture management apparel.

Not only do consumers buy this apparel, but many are willing to pay a premium for certain features. More than half of all consumers say they are “very or somewhat likely” to pay more for wrinkle (56%) and stain (51%) resistant clothing, followed by easy care (50%), fade resistant (46%) and stretch (45%).

Cotton Incorporated has addressed a number of these preferences with a variety of fabric technologies. In fact, according to the Cotton Incorporated Retail Monitor™ Survey, moisture management is the most common performance feature marketed at retail, followed by stretch, wrinkle resistance, and UV protection.

The company’s STORM COTTON™ finish is a water-repellent finish that offers protection from rain and snow. It maintains this repellency for the life of the garment, yet does not inhibit cotton’s breathability. The STORM DENIM™ technology brings the same benefits to jeans. The fabric breathes so wearers are comfortable, but moisture cannot penetrate from the outside. Such advantages are valuable across the board, whether for outdoor workers or urbanites caught in the rain.

The company’s STORM COTTON™ finish is a water-repellent finish that offers protection from rain and snow. It maintains this repellency for the life of the garment, yet does not inhibit cotton’s breathability. The STORM DENIM™ technology brings the same benefits to jeans. The fabric breathes so wearers are comfortable, but moisture cannot penetrate from the outside. Such advantages are valuable across the board, whether for outdoor workers or urbanites caught in the rain.

Meanwhile, the Cotton Incorporated TransDry® technology is a moisture-management application that allows fabrics to wick and spread perspiration horizontally and vertically, so clothes dry up to twice as fast as untreated cotton and do not become over-saturated with sweat during exercise. WICKING WINDOWS™ is a technology that eliminates the feeling of wet fabric against the body. Applied to the skin side of cotton apparel, it transfers moisture away from the body to the outside of the fabric. This way, it can evaporate during a workout, allowing the wearer to stay dry and comfortable while exercising.

Dewulf says recently launched skin-friendly and skin-enhancing fabric developments are also of great potential, with smart blending of natural and manmade fibers, including a focus on celluloses, mineral fiber technology or cosmetotextiles.

“Supported by accurate marketing initiatives and valid media information, these added value textiles will attract fresh consumer interest for activewear and beyond,” Dewulf says.

While some futuristic fabrics — like textiles that change from plain to patterned while being worn — are in the market, others are entering shortly, Johnson says.

“There will always be those who are into organics and don’t want things to change from the way they were originally made,” she concedes. “But these technologies make us safer or are helpful to us. It’s about science — and then, of course, we wiggle in a little fashion.”