The subject of outsourcing usually has to do with U.S. jobs that have been lost to overseas companies. But when the apparel industry outsourced its manufacturing, it also sent production to countries that have fewer pollution controls than exist in the U.S.

The Natural Resources Defense Council’s Linda Greer, director, health and environment program, says two major reports from Greenpeace and China’s IPE (Institute of Public and Environmental Affairs) underscore the importance of transparency in Chinese textile manufacturing.

“These reports show us that the curtain is rising, so to speak, on problems in manufacturing textiles in the developing world,” Greer says. “There is definitely an increasing sense of concern in the industry that it needs to get on top of these problems.”

[quote]The NRDC is encouraging the fashion industry to take a harder look at its supply chain, and keep track of its suppliers abroad through its Clean By Design program. It focuses on brands’ chosen fibers and chemicals, the manufacturing factories, ocean transportation of the goods and consumer care instructions.

Transparency in production has become more important to both brands and consumers. Witness the Cotton Life Cycle Assessment tool — an objective process that evaluates the potential environmental burdens associated with the entire life cycle of a specific product, process or activity. It is based on the Cotton Life Cycle Inventory, which quantifies information like energy, water, raw material requirements, air emissions, and other environmental releases that happen with a cotton product during its life cycle — from the time the cotton is farmed, through consumer use and its ultimate disposal.

“The cotton industry envisions a future where environmentally sustainable production and manufacturing will thrive along with the businesses that depend on cotton as a source of income,” says J. Berrye Worsham, president and CEO of Cotton Incorporated. “By 2050, we foresee the businesses that buy and sell cotton working hand in hand with conservation organizations to implement sustainable gains that can be readily verified by impartial measurement.”

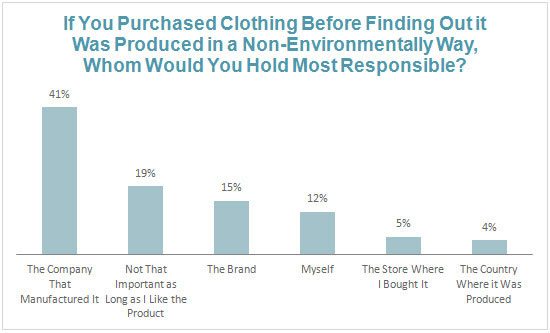

“Green” practices are environmentally important not only for businesses, but also for consumers. More than two-thirds (68%) of U.S. shoppers say they would be bothered if they found out an apparel item they bought was not produced in an environmentally friendly way, according to the Cotton Incorporated 2012 Environment Survey. Most (41%) would blame the company that manufactured it, followed by the brand (15%).

Gap Inc. is one of the companies Greer has worked with overseas on pilot programs that improve a factory’s environmental impact.

“We are continually looking for ways to reduce the impact we have on the environment in the communities across the world where we do business,” says Edie Kissko, Gap Inc. spokesperson. “Some examples include our branded denim that’s made in compliance with our Water Quality Program, which requires the facilities that launder our denim products to properly treat wastewater.”

Consumers will find Gap’s production transparency for its denim on a Water Quality Program label located on the interior pocket.

Even though just 27% of shoppers seek environmentally friendly apparel for themselves, down from 34% in 2008, 82% say they are concerned about air quality, followed by water quality/scarcity (78%), global warming (69%), products being made outside of the U.S. (65%) and clothes or fabrics treated with dyes, chemicals and bleaches (57%), according to the Environment Survey.

Even though Gap does not own or operate any factories, “We want to help ensure that the conditions under which our branded products are made are safe and fair,” Kissko says. “With our code of vendor conduct and thorough factory audits, we work to help ensure that our products are made in a way that is consistent with our social and environmental values.”

The Sustainable Apparel Coalition (SAC), of which Gap is a member, is an industry-wide group that works to reduce the environmental and social impacts of apparel and footwear products around the world.

Greer says the SAC members need address these ongoing environmental problems immediately and resolve impacts on a quick timeframe. “The credibility of the SAC will be seriously undermined if chronic, ongoing pollution problems are commonplace in textile mills manufacturing for its members.”

Cotton Incorporated, also a member of the SAC, points out that tools like its LCA data can aid in environmental decision-making by identifying key impact areas and benchmarking success over time. Already the data has:

- expanded research initiatives in water and nitrogen-use efficiencies;

- led those working with the LCA community to develop a more accurate model of agricultural toxicity impacts, including the incorporation of textile chemical profiles;

- continued support of wastewater reduction research in textile manufacturing; and

- educated consumers on sustainable garment care.

The NRDC states if just 100 small- to medium-sized textile mills implement NRDC’s recommended improvements, China would save more than 16 million metric tons of water annually, enough to provide 12.4 million people drinking water for a year.

Be it at the farming, production or consumer level, Kissko says the industry as a whole must face the environmental challenges together. “Multi-stakeholder collaborations and cross-industry partnerships are key.”

Greer agrees. “If the industry acts now, it will be able to stay ahead of the problems and threats to their brand reputation that are inevitable without change. If they drag their feet, they will find that they’re just reacting to bad news stories, rather than working proactively to prevent problems from occurring.”