Latest study sheds light on apparel industry’s role in plastic pollution, paving the way for sustainable solutions

CARY, NC — Cotton Incorporated and leading researchers published a groundbreaking study in Nature Communications, titled “The global apparel industry: a significant, yet overlooked source of plastic leakage.” This research reveals synthetic clothing contributes 7.4 million metric tons of plastic pollution annually. Most of this plastic leakage arises from macroplastic waste when synthetic clothes reach the end of their life cycle. This adds to the well-documented issue of microplastic shedding during the washing and wearing of these clothes.

The impact of synthetic garments on plastic pollution is staggering, with at least ten times more leakage than cotton clothing.”

Dr. Jesse Daystar, Vice President & Chief Sustainability Officer, Cotton Incorporated

“The impact of synthetic garments on plastic pollution is staggering, with at least ten times more leakage than cotton clothing,” said Jesse Daystar, Ph.D., vice president and chief sustainability officer at Cotton Incorporated. “Designing with natural fibers, like cotton, is one of the key strategies to reduce plastic leakage from the apparel industry.”

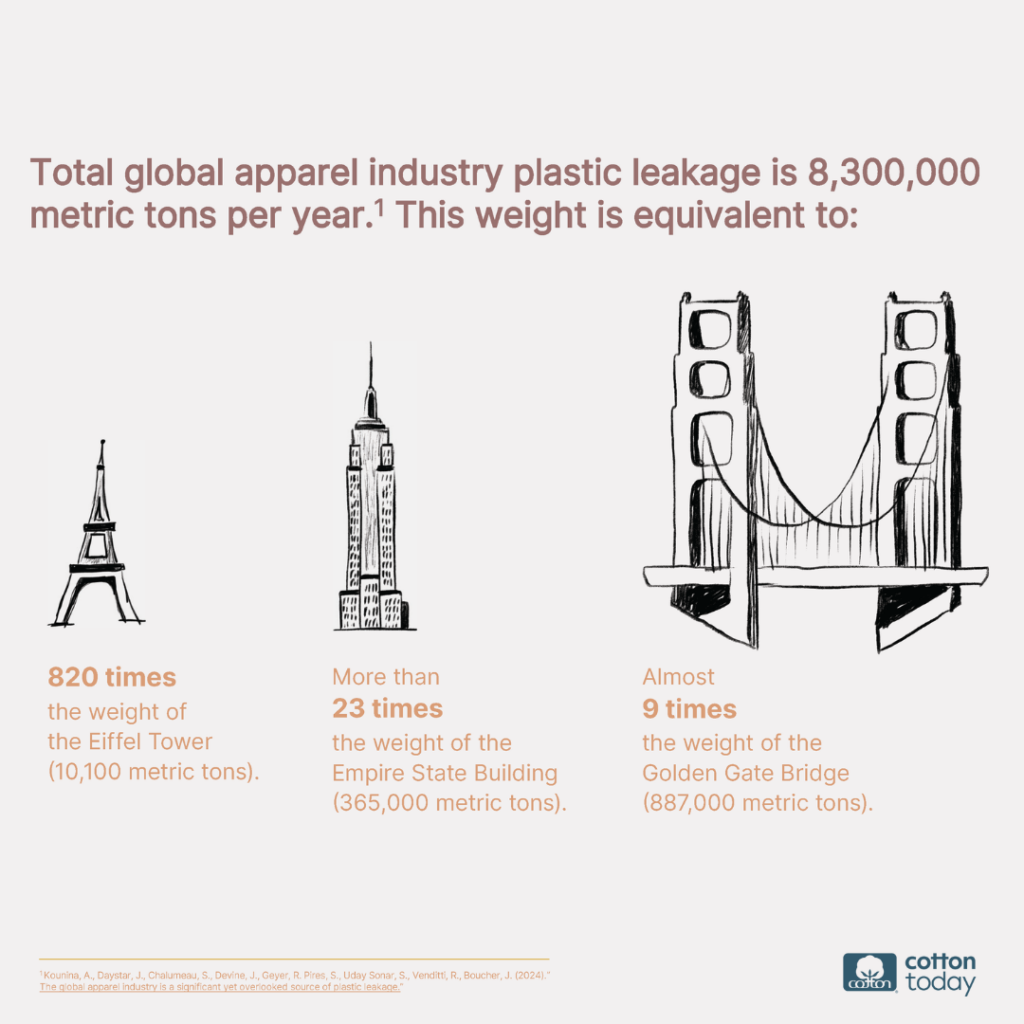

The report estimates that the global apparel industry contributes 14% of the total plastic leakage into the environment, which equates to approximately 8.3 million metric tons of plastic being released annually due mainly to the global production, use, and disposal of synthetic clothing. The term “plastic leakage” refers to the quantity of plastic released from human activity and pollutes the natural environment.

In addition to focusing on the selection and use of natural fibers like cotton, the study also recommends designing products for durability and prioritizing reuse, remanufacturing, and recycling as key strategies to reduce plastic pollution. However, the report also stresses the need to assess other environmental indicators, such as climate change and non-renewable resource use, in addition to plastic pollution.

While global cotton production contributes less than 1% of total plastic pollution, the cotton industry is actively pursuing solutions. Cotton Incorporated leads these efforts with innovative research aimed at reducing environmental impact. As a collaborator in the Plastic Leak Project (PLP), Cotton Incorporated helped develop the first-ever Methodological Guidelines, which provide businesses with tools to identify, measure, and address plastic leakage in their value chains. These guidelines were crucial for assessing plastic leakage in the apparel industry.

Methodology

This research quantified plastic leakage from the global apparel industry using the Plastic Leakage Project Methodology (https://quantis.com/who-we-guide/our-impact/sustainability-initiatives/plastic-leak-project/). The study’s methodology estimated the total mass of apparel consumed in each market by utilizing production and import data. For cotton apparel, net apparent consumption data was determined by adjusting domestic production, imports, exports, and losses throughout the value chain. In contrast, synthetic clothing consumption was deduced from import data or assumptions about the proportion of apparel consumption attributed to cotton, due to its broader range of end-uses. Other types of fibers were accounted for in a similar manner. To learn more about the research methodology, please visit https://doi.org/10.1038/s41467-024-49441-4 . For a summary of the key research findings, see the topline report.

About Cotton Incorporated

Cotton Incorporated is a research and promotion company for upland cotton. Funded by U.S. cotton growers and importers of Upland cotton-containing products, the not-for-profit organization’s mission is to increase the demand for and profitability of cotton. As a resource for the cotton industry, Cotton Incorporated conducts or oversees more than 450 research and educational projects in an average year. To learn more, visit CottonToday.com and follow along on Facebook, LinkedIn, X (formerly Twitter).