If there’s one word coming out of fashion in 2024, it’s “sustainable.” And while there are many thoughts on what the word means and how to achieve sustainability, one area is being viewed as not just eco-conscious but cost effective: digital product creation (DPC), or digital design.

Originally seen as clothing to be worn by an avatar or in a video game, not in real life, digital fashion is the visual representation of clothing that’s created using computer technologies and 3D software.

“The reality of digital design really dropped in 2020 as a more efficient, effective and sustainable solution,” says Clare Tattersall, director of Digital Fashion Week and founder of The Drip, a haute couture digital fashion boutique, in an interview with the Lifestyle Monitor™. “However, I don’t think there can be any one single answer for designers as the adoption rate is very wide, depending on the size of the brand. Those who have adopted digital design as an option can recognize the benefits, but many have not yet adopted this as an option.”

“Independent designers are seeing the value of digital design, both as an efficient and effective tool, but also for the broad opportunities that this opens up for diverse revenue streams.

Clare Tattersall, Director of Digital Fashion Week & Founder of The Drip

Both novices in digital design as well as those familiar with the technology are invited to learn more about it as well as get more hands-on experience through Cotton Incorporated’s CottonWorks™ virtual showroom and its FABRICAST™ library.

Cotton Incorporated’s Katherine Absher, manager of fashion and digital design marketing, describes digital fabrics as a representation of a finished physical fabric, only they’re used in 3D apparel design software such as CLO and Browzwear 3D.

“You may have heard them described as digital fabrics, digital twins, virtual fabrics – but they all mean the same things,” Absher says. “Essentially, digital fabrics are like a twin for the physical counterpart. They recreate the look and the drape of the physical fabric.”

Of note to manufacturers: Brands can save time and money with digital design. The process enhances the design process and reduces waste. By using digital fabrics and 3D design software, brands can replace some or all physical clothing samples, are able to reduce their traditional calendar lead times, are able to make faster decisions and have more time to iterate – which can lead to overall better designs that are adopted at a higher rate than physical samples.

For example, if the traditional calendar can take a year from concept to point of sale, digital design can reduce that to six months. How? Consider that it can take 45 days to produce a physical sample. Any significant changes to the original sample call for revised samples, adding even more time to the original month and a half. By comparison, a digital sample can be made in 14 days.

Further, when companies use fewer physical samples, they reduce consumption of raw materials and sample yardage, leading to reduced shipping costs and a lower freight carbon footprint.

Sustainability isn’t just a talking point. It’s something that’s truly valued by today’s shoppers. Consider that a notable 86 percent of global consumers say environmental change and sustainability are “very real” and require changes in our behaviors, according to Cotton Council international and Cotton Incorporated’s 2023 Global Sustainability Study.

Brands looking to improve their environmentally conscious quotient can turn to The CottonWorks™ virtual showroom, where sustainability meets technology. Designers who visit the virtual showroom start their journey in a sun-drenched cotton field and are quickly zoomed up to a bright and airy space that demonstrates what modern cotton fabrics can do. The showroom features four uniquely curated spaces – right now they’re focused on “natural,” “denim,” “active” and “competition.”

Each showroom space presents a variety of fabrics and fashion-forward garments aimed at sparking designers’ imaginations. The showroom promotes both specific products such as denim bottoms as well as entire categories like performance activewear. But the showroom goes beyond merely introducing these fabrics; it allows users to view pieces in 3D right on their computer screens. Additionally, users can take a snap of a QR code with their smartphone so they can view a showroom garment right in their own space. Designers can also learn about performance technologies that work with cotton, such as TransDRY® and STORM COTTON™Technologies.

The CottonWorks™ FABRICAST™ library also offers designers a digital collection of cotton and cotton-rich fabrics carefully curated by its product development team. Designers can view digital fabrics across a variety of constructions through downloadable files that are compatible with 3D simulation software programs. Of note: the library, the showroom, the downloadable files and everything else available on CottonWorks™ are available at no cost.

“Independent designers are seeing the value of digital design, both as an efficient and effective tool, but also for the broad opportunities that this opens up for diverse revenue streams,” says Tattersall. “You have brands like Tommy Hilfiger that made a very rapid transition to be completely digital. They set goals and achieved them on a very tight schedule, which was pretty impressive for a large brand. Independent designers are more nimble and able to adopt new technologies faster, the most prohibitive factor for independents is probably cost. In the independent sector, there are so many designers like Republiqe, Loreine, Right Direction, KAIMIN that are truly phygital designers, layering digital and physical assets seamlessly.”

Digital product design has another sustainability aspect: It can also help brands reduce returns. Brands can use digital fabrics and 3D design to troubleshoot fabric choices and fit issues as well as fabric compatibility. Tech teams can match what is developed in 3D so there is a consistency between what customers see online and what they receive in real life. When customers feel like what they receive in real life is what was represented online, customer satisfaction increases while returns decrease.

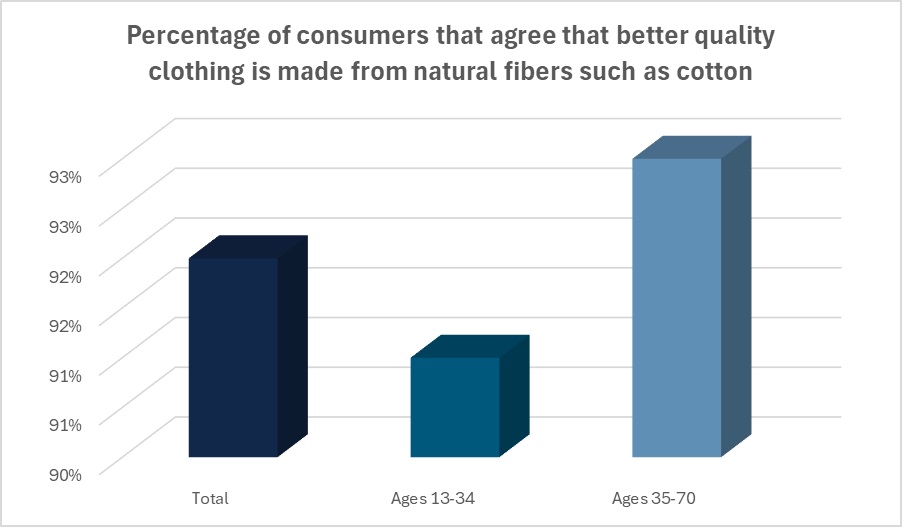

Designers and brands can be assured that all of the digital fabrics in the CottonWorks™ library are sustainable because they are all natural cotton. This is meaningful to consumers on multiple levels. For starters, fully 92 percent of consumers think better quality garments are made from all natural fibers, according to 2023 Cotton Incorporated’s Lifestyle MonitorTMSurvey. Further, nearly three-quarters of all shoppers (72 percent) are willing to pay more for natural fibers such as cotton.

Not only are cotton and cotton blends (including denim) the favorite fiber or fabric to wear for the majority of consumers (71 percent – eclipsing others including silk (4 percent), polyester (3 percent) and wool (1 percent) – but 79 percent say cotton/organic cotton/recycled cotton is safe for the environment.

The fashion industry’s relationship with textiles matters to consumers, Mother Earth and business overall. The care and disposal of garments and the biodegradability of raw materials, both natural and synthetic, is an important topic throughout the supply chain. Studies show cotton is far more biodegradable than petroleum-based fabrics like polyester. In one study, cotton samples decomposed up to 77 percent in just 90 days, while most polyester fibers remained intact.

Cotton biodegrades quickly because it is made of cellulose, an organic compound that is the basis of plant cell walls and vegetable fibers. The fibers break down naturally in landfills similarly to other crops such as food and plants. The Council for Textile Recycling reports an incredible 85 percent of America’s used clothes goes to landfills.

With sustainability and biodegradation in mind, designers should note that Cotton Incorporated has developed viable alternatives to synthetic microfiber fleece by creating cotton and cotton/wool blend fabrics that are designed to insulate and provide warmth – while offering a natural, biodegradable option. Further, any fibers that shed from garments made with these fabrics easily break down in soil and water environments. Polyester fibers, conversely, contribute to the microplastic pollution problem and can take hundreds of years to decompose.

Whether it’s 3D design or discovering fabrics through digital libraries, digital product creation is still in its early days, giving designers and brands much to work with and think about when it comes to their business and sustainability goals.

“These are very broad concepts really, and it shows just how many options there are available for designers now,” Tattersall says. “Definitely in our community, we see huge adoption of technology and great excitement when a designer’s needs are met by innovation. Starting with design tools is at the root. And once you have digital designs, they can be translated to different formats – taken into the gaming industry, integrated into technology at the point of sale and chipped for communication (think digital product passports) with the customer on a longer term basis.”