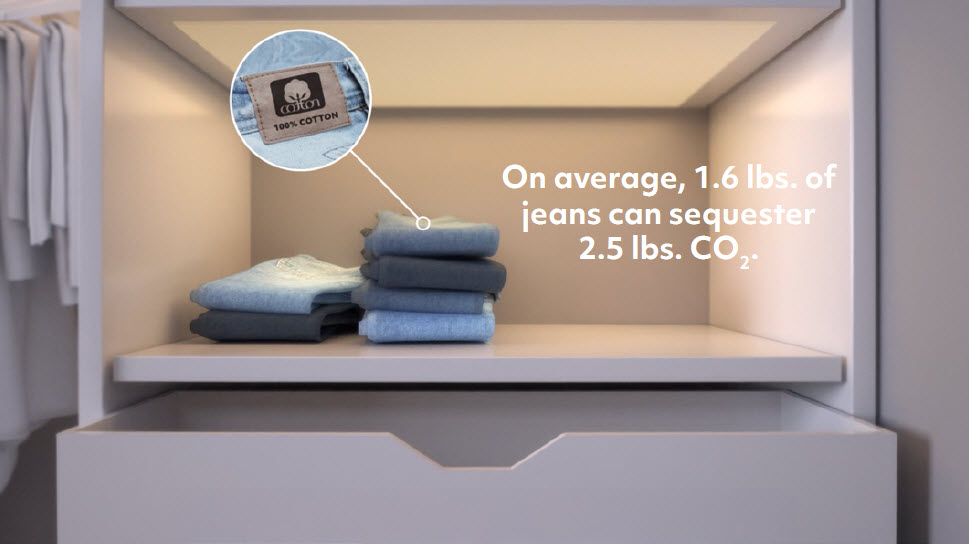

Cotton is a natural, plant-based fiber composed primarily of cellulose (95%), a natural polymer and the main ingredient of plant cell walls. Cotton lint is about 95% cellulose, and cellulose contains roughly 44% carbon by mass.1 This means each kilogram of cotton fiber contains about 0.42 kg of biogenic carbon—equivalent to roughly 1.55 kg of CO₂ absorbed from the atmosphere during growth*. This carbon is biogenic, meaning it originates from the natural carbon cycle rather than from fossil fuels. This makes cotton a renewable, plant-based material whose carbon is part of a closed biological loop—absorbed from the air, stored in the fiber, and eventually returned to the environment.

Every cotton product—from clothing to home textiles—acts as a temporary storage reservoir for atmospheric carbon during its use and reuse phases.2 In contrast, synthetic fibers such as polyester are made from fossil-derived carbon, introducing new carbon to the atmosphere rather than cycling existing carbon through natural systems.

*Cotton ≈95% cellulose, and cellulose (C₆H₁₀O₅) contains 6 carbon atoms per 162 g (44.4% carbon by mass). Converting carbon to CO₂ uses the molecular weight ratio 44.01/12.01 = 3.664. Thus: 1 kg cotton × 0.95 × 0.444 × 3.664 ≈ 1.55 kg CO₂ stored in the fiber.

Source: Every unit of carbon removed from the atmosphere represents 3.667 units of CO₂ removed (based on the molecular formula of carbon dioxide) Source: Wakelyn, P.J. (2006). Cotton Fiber Chemistry and Technology (1st ed.). CRC Press. Chapter 3 Source: United States Environmental Protection Agency (2022). Greenhouse Gas Equivalencies Calculator.

What happens to the carbon stored in cotton during the product lifecycle?

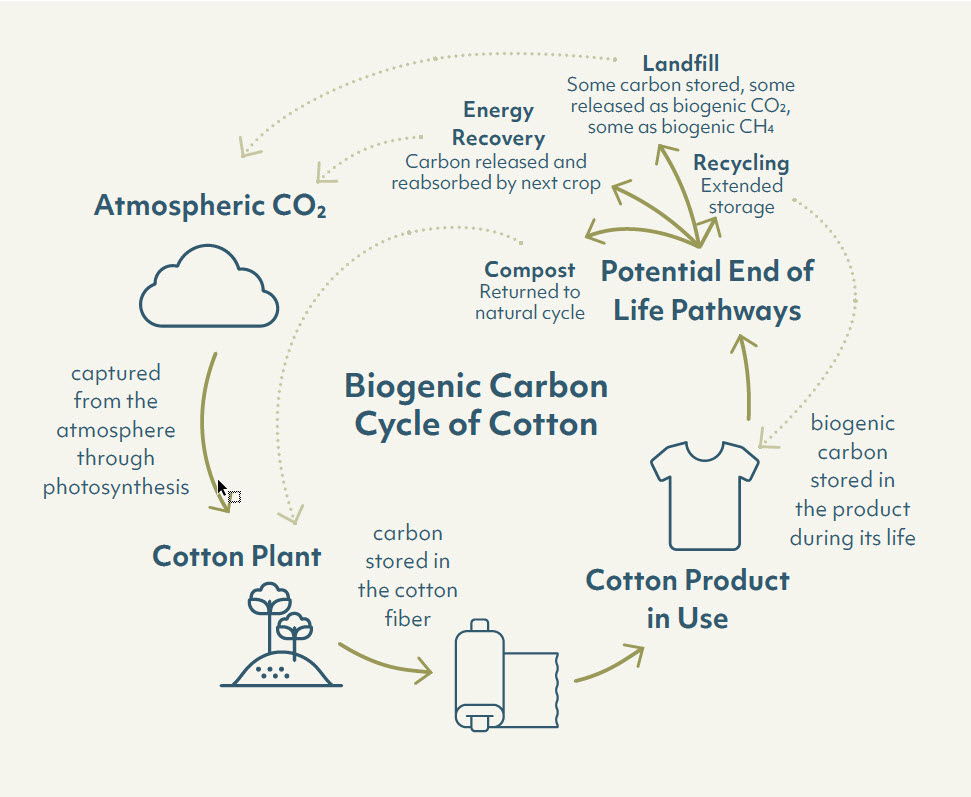

Cotton’s carbon journey begins in the atmosphere, where plants capture CO₂ through photosynthesis. This biogenic carbon is sequestered in the cotton fiber and remains stored throughout the product’s lifecycle. When recycled, that storage continues in the next product; when composted or used for bioenergy, the carbon returns to the biosphere and re-enter the natural carbon cycle. Unlike synthetic fibers made from fossil carbon, which add new carbon to the atmosphere, cotton cycles existing carbon through renewable storage pathways.2,3

How do the carbon source and fate differ between cotton and synthetic fibers?

Cotton’s carbon originates from CO₂ captured in the atmosphere during plant growth, making it part of the natural biogenic carbon cycle. In contrast, polyester and other synthetics are made from petroleum, introducing fossil carbon from underground reserves into the atmosphere when produced and eventually discarded.

Because cotton is a natural, cellulose-based fiber, it also biodegrades in soil, compost, and aquatic environments4,5 —returning its carbon to the biosphere as part of the natural carbon cycle and preventing the accumulation of persistent macroplastic and microplastic waste. Synthetic fibers, by contrast, resist biodegradation and can persist for decades or centuries, leaving fossil carbon permanently outside the natural cycle.

How long does cotton store carbon?

The carbon captured during cotton’s growth remains sequestered in the fiber for the full life of the product, whether it is being used, reused, or kept for future use. In typical apparel, this may be several years.2 If cotton is reused, recycled, or converted into long-lived products such as building insulation or biochar, carbon storage can extend for decades or longer.2 The longer the carbon is stored, the greater the environmental benefit.2 At any given time, hundreds of millions of tons of atmospheric carbon are temporarily stored in cotton textiles worldwide.

What happens at the end of a cotton product’s life?

At the end of its life, cotton’s carbon returns to the environment through natural processes. In aerobic composting, microorganisms break down the cellulose, releasing CO₂ that can be reabsorbed by plants.6 In anaerobic landfill conditions, decomposition is slower, and some carbon may remain sequestered for long periods, although methane can be produced.6

Circular end-of-life strategies—such as reuse, recycling, or conversion into materials like building insulation—prolong carbon storage and help avoid methane emissions from landfills.

What factors influence cotton’s carbon profile?

Cotton’s role as a carbon store is inherent to the plant, but certain factors can enhance its environmental benefits:

Farming practices such as cover cropping, reduced tillage, and improved nutrient management can increase soil carbon sequestration and reduce on-farm greenhouse gas emissions.2

Product design that emphasizes durability extends the storage period.2

End-of-life pathways that keep products in use or recycle cotton into long-lived products keep carbon out of the atmosphere for longer.2

Why does biogenic carbon storage matter?

Biogenic carbon storage highlights the difference between renewable, plant-based fibers and fossil-derived synthetics. Atmospheric carbon is stored during a cotton product’s use phase, acting as temporary carbon sinks. When combined with regenerative agricultural practices, thoughtful product design, and circular end-of-life strategies, cotton’s natural carbon storage potential can be maximized offering a measurable environmental benefit that sets it apart from synthetic fibers.

1 Phillip J. Wakelyn, Noelie R. Bertoniere, Alfred D. French, Devron P. Thibodeaux, Barbara A. Triplett, Marie-Alice Rousselle, Wilton R. Goynes Jr, J. Vincent Edwards, Lawrance Hunter, David D. McAlister, & Gary R. Gamble. (2007). Cotton Fiber Chemistry and Technology (M. Lewin, Ed.; Vol. 17). CRC Press. https://doi.org/10.1201/9781420045888

2 Pires, S. T., Williams, A., Daystar, J., Sagues, W. J., Lan, K., and Venditti, R. A. (2024). “Evaluating cotton apparel with dynamic life cycle assessment: The climate benefits of temporary biogenic carbon storage,” BioResources 19(3), 5074-5095. DOI: 10.15376/biores.19.3.5074-5095

3 IEA Bioenergy (2025). Fossil vs biogenic CO2 emissions. https://www.ieabioenergy.com/iea-publications/faq/woodybiomass/biogenic-co2/

4 Zambrano, M. C., Pawlak, J. J., Daystar, J., Ankeny, M., & Venditti, R. A. (2021). Impact of dyes and finishes on the aquatic biodegradability of cotton textile fibers and microfibers released on laundering clothes: Correlations between enzyme adsorption and activity and biodegradation rates. Marine Pollution Bulletin, 165, 112030. DOI: 10.1016/j. marpolbul.2021.11203

5 Lili, M. F., & Browning, K. J. (2010). Biodegradability Study on Cotton and Polyester Fabrics. Journal of Engineered Fiber and Fabrics, 5(4), 42-53.). DOI:10.1177/155892501000500406

6 Hubbe, M.A., Daystar, J.S., Venditti, R.A., Pawlak, J.J., Zambrano, M.C., Barlaz, M., Ankeny, M., Pires, S. (2025). Biodegradability of Cellulose Fibers, Films, and Particles: A Review. BioResources20(1), 2391-2458. DOI: 10.15376/biores.20.1.Hubbe