A recent viewing of a show about tiny houses featured a man who needed to get rid tons of “stuff,” including a lot of clothes, before his family could transition to their tiny home. He said he kept many of his things because he didn’t want them to end up in a landfill. One way fashion brands can help in this battle to keep textiles out of landfills is by making better quality, more durable clothes with natural fibers like cotton – even for high fashion, high-performance or technical apparel. It’s an endeavor made easier with industry resources found right at one’s fingertips.

The natural narrative of cotton speaks to sustainability. Cotton in its natural cream colored form is beautiful and doesn’t require dyes to be aesthetically pleasing. We are also exploring dyes and pigments derived from earth minerals to apply color to cotton fabrics.

Yvonne Johnson, Senior Director, Product Development at Cotton Incorporated

To be sure, the tiny house homeowner’s concern about loading a dump with apparel is valid. As it stands, 100 billion garments are produced each year and more than 101 million tons of clothes end up in landfills, according to Earth.org. This is the equivalent of a garbage truck full of textiles being dumped every second. Now consider that 62 percent of all fibers used in fashion are made from petroleum-based textiles like polyester, nylon, and acrylic. The problem here is multi-fold: petroleum-based textiles can take hundreds of years to decompose. The synthetic apparel also releases tiny plastic fibers known as microplastic pollution into the ground and air while it sits in the landfill. The microscopic fibers can then also find their way into waterways, contaminating both the food chain and drinking water. Additionally, as clothing degrades in landfills it releases methane, which Action for Climate Emergency describes as being 28 times more powerful than carbon dioxide.

But back to how fashion brands can help reverse this course. First, the fashion industry should keep in mind that although cotton garments also shed fibers during wear and laundering, they can biodegrade in both soil and water many times faster than petroleum-based synthetics because cotton is made of cellulose, an organic compound that is the basis of plant cell walls and vegetable fibers.

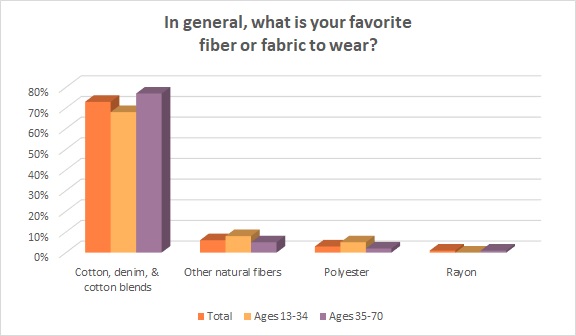

Further, the majority of U.S. consumers (73 percent) say cotton, denim, and cotton blends are their favorite fabric to wear, according to Cotton Incorporated’s Lifestyle Monitor™ Survey. And fully 72 percent of shoppers say they would pay more for apparel made from natural fibers like cotton.

Knowing all this about consumer preferences, brands can expand their usage of cotton and cotton-rich fabrics by tapping into the CottonWorks™ FABRICAST™ library. The online collections have been curated by Cotton Incorporated’s product development team, with new entries added throughout the year to provide ideas, innovation, and inspiration for design teams each season. Access is free to anyone who signs up for a free CottonWorks™ account. Users can browse through the extensive fabric library and download digital files that are compatible with CLO3D and Browzwear. Digital fabrics can be viewed in 3D and augmented reality, which overlays a 3D model of the fabric into the user’s physical space through their smartphone.

The digital fabrics allow designers to iterate and visualize new styles much faster than traditional physical sampling allows. This reduces physical sampling, decreases waste and time to production, and conserves resources associated with manufacturing, shipping and garment sample storage. Once digital prototypes are made, they can be used further in sales presentations and consumer marketing. The CottonWorks™ site also offers webinars that offer an introduction to digital fabrics as well as best practices in the creation process.

“The textile design engineers at the Cotton Incorporated Research Center in Cary, NC start the design and development process with sustainability at top of mind. Reducing time, energy, water and chemistry inputs contributes to lower environmental impacts,” says Yvonne Johnson, senior director, product development at Cotton Incorporated. “The natural narrative of cotton speaks to sustainability. Cotton in its natural cream colored form is beautiful and doesn’t require dyes to be aesthetically pleasing. We are also exploring dyes and pigments derived from earth minerals to apply color to cotton fabrics.”

The digital fabrics can be viewed through the CottonWorks™ Virtual Showroom, an innovative platform that allows users to engage and interact with these fabrics right from their desks. The Virtual Showroom, which launched last year, explores a variety of fabrics and fashion-forward designs under Active, Natural, and Denim spaces. All can be viewed on a computer screen or in AR by clicking on a QR code with a smartphone.

Designers and manufacturers can also just learn about the many types of cotton fabrics available through the FABRICAST™ collections. These include knits, wovens, and digital fabrics, as well as a section that shows new releases such as synthetic fleece alternatives, finishing techniques, and more. For example, a user looking for a moisture-wicking knit could find a 100 percent cotton jacquard with moisture-management technology. Or perhaps a designer is looking for a soft, 100 percent cotton double knit that repels water – that can be easily found, as well. Wovens include something as ornate as a puff pigment print on heavyweight canvas, a printed cotton dobby stripe shirting with 100 percent cotton stretch technology, as well as all-cotton twill with water repellant finishing.

“Exciting new developments the textile designers at Cotton Incorporated have planned this year revolve around texture and more texture,” adds Johnson. “There are cozy cotton dobby weaves for throws, a winter cotton collection of tweedy knitwear, wide wale corduroy, elevated utilitarian woven fabrics for pants and jackets, and loopy terry knits for sweatshirts and casual tops.”

Users can also learn more about performance technologies that work with all-cotton and cotton-rich fabrics. Technologies include TransDRY® Technology for high performance moisture management (perfect for activewear), STORM COTTON™ Technology, a durable water repellent finish for outdoor cotton apparel, and TOUGH COTTON™ Technology, a technology that adds increased durability, abrasion resistance and wrinkle resistance to cotton fabric throughout the life of the garment.

Interested in learning more about Cotton Incorporated’s Virtual Showroom experience? Check out the recent fireside chat with Katherine Absher, fashion and digital design manager at Cotton Incorporated, and Jessica Binns, managing & technology editor at Sourcing Journal.