While Earth Day is happening on April 22, all of April is considered Earth Month, giving ample opportunity for the industry to really consider its sustainability efforts. Where fashion and textiles are concerned, that can mean increasing efficiency. One way to achieve that is through Cotton Incorporated’s Engineered Fiber Selection® (EFS®) System Suite of software.

The EFS® System Suite is a logistics, evaluation, and optimization package designed to improve the profitability of cotton from the time it leaves the bale press until it is made into yarn. The system works to produce consistently high-quality yarns, which is essential for producing consistently high-quality fabrics. Vikki Martin, Ph.D. and vice president of fiber competition for Cotton Incorporated, says improved fiber quality can help the spinning industry more efficiently process cotton.

EFS® is critical to helping us interpret the cotton properties that we’re getting into our facilities and how we can better utilize those materials to make the best end product that can be made from a quality standpoint.

Johnny Mauney, Cotton Quality Manager, Gildan Yarn

“Ginners work to clean the fiber with the least damage possible,” Martin says. “Fiber quality improvements and preserving that fiber quality through ginning allow textile mills to source the qualities they need. One of our goals for improvement specifically targets properties such as length uniformity – length distribution within a bale. Better length uniformity means more of the fibers in the bale are of similar length and, therefore, are easier to process.

“Mills can also make use of bale management systems like EFS®,” Martin continues. “A good bale management system (EFS®) can help the mill better utilize its inventory and create consistency in its yarn. They can source only the fiber qualities needed and not overbuy, which means buying fiber quality higher than required just to ensure good efficiency and quality in the product. The control given through EFS® helps with spinning efficiency, which helps productivity. And mills using EFS® can specifically provide information to their customers about the origin of cotton used to document the use of better or preferred cotton.”

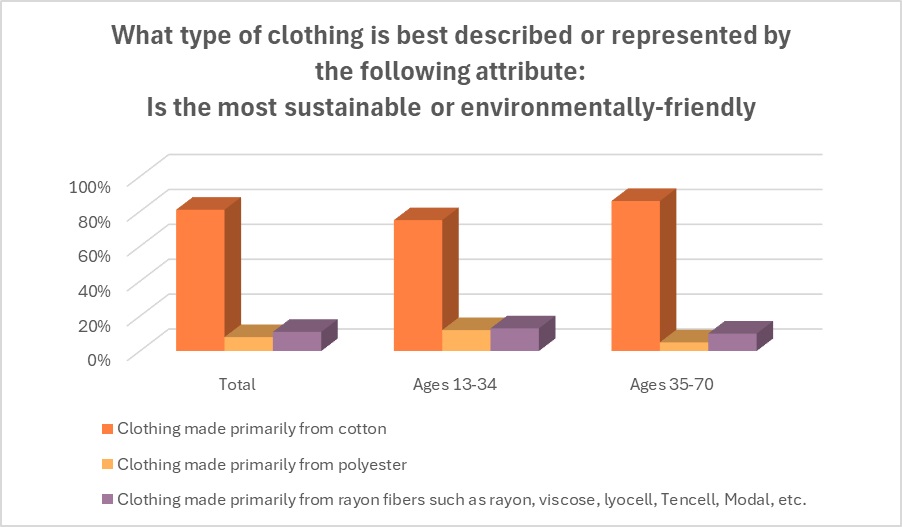

Over 8 in 10 consumers (78 percent) say clothing primarily made from cotton is the most sustainable/environmentally-friendly and highest quality (73 percent) compared to manmade fiber clothing, according to the 2023 Cotton Incorporated Lifestyle Monitor™ Survey. Nearly two-fifths of consumers say sustainability or environmental friendliness is important to them when they are looking at what brands to buy, according to the 2022 Lifestyle Monitor™ Survey.

Because the EFS® System Suite, which is celebrating its 40th anniversary this year, benefits the spinning mills, it stands to benefit manufacturers, as well.

Martin explains that the EFS® System Suite consists of three components: USCROP™ Software, Cotton Communicator™ Software, and the flagship MILLNet™ Software.

“USCROP™ is a software tool that is utilized by cotton buyers to see the quality of the cottons that are available in a given crop year,” Martin says. “Cotton Communicator™ allows for data exchange of high volume instrument information on fiber quality between cotton buyers and cotton sellers. MILLNet™ is a bale management system that allows for textile mills to assess what they have available in the inventories to make the correct selections for appropriate laydowns to create consistent quality products.”

Gildan Yarn’s Johnny Mauney, cotton quality manager, says his company relies on EFS® technology.

“EFS® is critical to helping us interpret the cotton properties that we’re getting into our facilities and how we can better utilize those materials to make the best end product that can be made from a quality standpoint,” Mauney says.

And quality is a factor that matters to consumers. Consider that the majority of shoppers (70 percent) say they would rather have fewer, higher quality items of apparel than more items of lesser quality, according to 2022 Monitor™ research.

This desire dovetails with one of the goals of Earth Day 2024: to achieve a 60 percent reduction in plastic production by 2040 in part by “demanding policies ending the scourge of fast fashion and the vast amount of plastic it produces and uses.” Earthday.org states the fast fashion industry annually produces more than 100 billion garments. It posits that overproduction and overconsumption have transformed the industry, leading to “the disposability of fashion.” Earthday.org says consumers now buy 60 percent more clothing than 15 years ago, but each item is kept for half as long.

“Approximately 85 percent of garments end up in landfills or incinerators, with only 1 percent being recycled,” Earthday.org states. “Nearly 70 percent of clothing is made from crude oil, resulting in the release of dangerous microfibers when washed and continued contribution to long-term pollution in landfills.”

Over one-third of consumers (45 percent, up from 30 percent in 2020) say they are aware of current concerns about microfibers polluting our oceans and waters, according to the 2024 Monitor™ research. Consumers aged 13-to-34 (51 percent) are significantly more likely to say they are aware of this microplastic pollution concern.

Of note, over two-fifths of consumers (44 percent) say they are bothered by brands and retailers using synthetic fibers in their clothing because of microplastic pollution, according to the Monitor™ research. And 71 percent of those who are aware of microplastic pollution say this will affect their future apparel purchase decisions.

Instead of synthetic apparel, consumers may likely be looking for natural fibers considering the majority (81 percent) say cotton clothing is the most sustainable, highest quality (73 percent) and lasts the longest (67 percent) compared to manmade fiber apparel, according to 2023 Monitor™ research.

The textile industry can ensure it’s consistently delivering the high-quality cotton yarns consumers expect by working with the EFS® System Suite. As Cotton Incorporated states, the EFS® Suite allows gins, merchants and mills to put the right cotton in the right place at the right time.