When thinking about cotton products, it makes sense that the first thoughts turn toward apparel — the denim jeans, the dress shirts, the tees, etc. – especially if you’re in the fashion industry. But interesting innovations are giving new uses to this traditional fiber, both as new products and an end-of-life usage. Bonus: These initiatives are great for apparel makers looking to improve the sustainability aspect of both their brand and their offerings.

Eco-consciousness comes into sharp relief when one considers the average U.S. consumer throws away about 82 pounds of clothes every year, which adds up to 11.3 million tons of textile waste in landfills, according to Earth.org. On top of that, 62 percent of all fibers used in fashion are made from petroleum-based textiles like polyester, nylon and acrylic. These synthetic fibers can take hundreds of years to decompose and release microplastic pollution into the ground, air and water supplies while it sits in the landfills. Not only that, reports have shown as clothing degrades in landfills, it releases the greenhouse gas methane, which is 28 times more powerful than carbon dioxide.

But clothing isn’t the only wardrobe item hitting the garbage dumps. Americans are also throwing away at least 300 million pairs of shoes each year, parts of which reportedly can last up to 1,000 years in a landfill.

This exciting research presents a new opportunity to create new things from cotton textile waste.

Matt Farrell, Manager, Textile Chemistry Research at Cotton Incorporated

Enter a natural solution to some of these issues. First, the shoe situation. Cotton Incorporated researchers have developed a 100 percent cotton 3D shoe upper prototype using Shima Seiki and Stoll flat knitting machines. The idea is that the fully fashioned knitting machines will ensure minimal to zero yarn and fabric waste. The resulting shoe upper is also washable. Added features such as eyelets, loopholes, and tongues can also be added without compromising the integrity of the knitted upper.

“The uppers represent an important step on the path to more environmentally friendly shoes, without sacrificing quality or performance,” states Cotton Incorporated. “The cotton shoe uppers easily support customized embellishment such as digital printing and dyeing, as well as attached stitched logos with the same wearability and durability as a synthetic upper. It’s an innovative way to bring this feel-good fiber to footwear.”

Performance technologies such as TOUGH COTTON™ and STORM COTTON™ technology could also be applied to the shoe uppers to make them both waterproof and more durable.

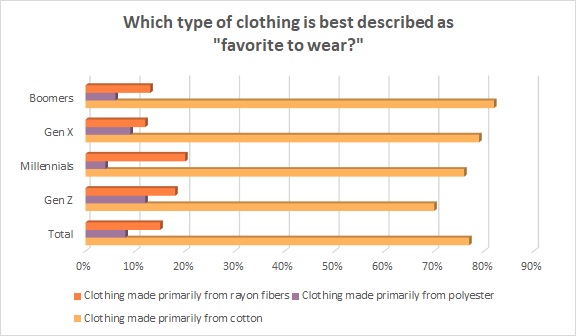

As it stands, nearly 8 in 10 consumers (77 percent) say clothing made primarily from cotton is their favorite to wear, according to the 2023 Cotton Incorporated Lifestyle Monitor™Survey. Additionally, 81 percent say cotton is the most sustainable. It stands to reason consumers would appreciate less waste, as well, when manufacturers use their favorite fiber to produce both apparel and footwear.

Such innovation would likely be welcomed by those designers already using cotton in their footwear. Take, for example Christian Cowan, whose Fall/Winter 2024 show during New York Fashion Week included a collaboration with footwear maker TOMS. The capsule collection contained the classic Alpargata slip-on, the white pair of which is made with recycled cotton uppers lining and sock liner. The sensible style was made new with a giant blossoming peony.

“The flamboyance of the blossoming peony juxtaposed with raw and durable fabrics is so fresh,” Cowan states. “I love how these designs merge the magic of our runways with the ease of wearable and comfortable design. These are those shoes that you get and wear every single day, and forget about all your other shoes.”

Reducing waste in production goes beyond footwear, though. Cotton Incorporated’s textile experts have also been working on knit-to-shape technology that is specific to cotton textiles and can create different “zones” within a single garment, body-mapped to match the wearer’s needs. Cotton Incorporated’s knit-to-shape grouping includes three body-mapped athleisure tanks. One design uses TransDRY® technology for moisture management. This particular knit-to-shape method decreases the volume of cutting waste and dead stock.

These innovations all work for making new products with natural cotton. But one new project is giving yet another sustainable twist to the end-of-life of a garment. Research is underway that can turn worn garments into glucose – or sugar. While the idea of turning a cotton shirt into cotton candy sounds amazing, this isn’t actually how the process works.

Cotton Incorporated teamed with North Carolina State University (NCSU) to develop environmentally and economically feasible ways to turn discarded cotton textiles into glucose. Sure, glucose is used in sweets, but it is also the main raw material used to produce ethanol, which is a biofuel. Glucose can also be used to produce value-added chemicals such as levulinic acid, succinic acid, and lactic acid. Lactic acid is used in the cosmetics industry to manufacture hygiene and esthetic products as it has moisturizing, antimicrobial, and rejuvenating effects on the skin. In the food industry, it’s used in the production of yogurts and cheese.

Traditionally, many of these chemicals are actually produced from petroleum. But making them from discarded cotton textiles could directly decrease greenhouse gas emissions. The process uses enzymatic hydrolysis, where enzymes turn the cellulose in cotton into more basic molecules – like glucose. This process also helps deal with the complexities associated with textile waste, such as blends of natural fibers with synthetics. See, the efficient conversion of cotton textiles into glucose could allow the downstream separation and recycling of other synthetic and non-biodegradable fibers.

This kind of circularity in fashion is important to the majority of consumers (63 percent), according to the 2023 Cotton Incorporated Consumer Circularity Survey. In order to achieve better circularity, most consumers (75 percent) would like to see fashion companies use more cotton in their apparel.

Matt Farrell, textile chemistry research manager at Cotton Incorporated, points out that this conversion initiative represents an alternative to repurposing, recycling or disposing of worn garments.

“This exciting research presents a new opportunity to create new things from cotton textile waste.”